Precision at Its Best: Aluminum Prototype Manufacturing and Machining by Sanwometal

Imagine a world where your innovative ideas quickly transform into tangible, high-quality prototypes. Aluminum prototype manufacturing and aluminum prototype machining make this possible, bridging the gap between design concepts and final products. At Sanwometal, we take pride in delivering precision-engineered prototypes that help businesses in the USA achieve their development goals. Let’s explore how these techniques can revolutionize your projects.

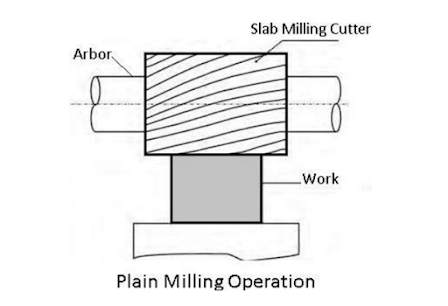

|

| aluminum prototype machining |

Why

Aluminum Prototypes Are Essential

Prototyping plays a critical role in

product development, offering the opportunity to test designs before full-scale

production. Aluminum stands out for prototyping because of its unique

properties:

- Lightweight and Strong: Aluminum combines durability with a lightweight

nature, making it perfect for applications requiring strength without

extra weight.

- Corrosion Resistance:

Its natural resistance to corrosion ensures long-lasting prototypes.

- Cost-Efficiency:

Aluminum is affordable and widely available, reducing manufacturing costs.

- Easy to Machine:

The material’s machinability allows for intricate and precise designs.

At Sanwometal, we specialize

in delivering aluminum prototypes tailored to diverse industries, including

automotive, aerospace, and consumer electronics.

The

Process of Aluminum Prototype Manufacturing

Design

and Consultation

Every great product starts with a

solid design. We work closely with clients to understand their needs, ensuring

the prototype aligns with their vision.

Material

Selection

Choosing the right aluminum alloy is

crucial. Options like 6061 and 7075 offer varying benefits, such as strength or

machinability, depending on your application.

Precision

Machining

Using advanced CNC aluminum

machining, we craft prototypes with exceptional accuracy. This method

ensures consistent quality, even for complex designs.

Testing

and Validation

Prototypes are rigorously tested to

verify performance, durability, and compatibility with the intended

application.

Finishing

Touches

From anodizing to powder coating, we

offer a variety of finishes to enhance durability and aesthetic appeal.

Benefits

of Aluminum Prototype Machining

Sanwometal uses cutting-edge technology to deliver unmatched precision

in aluminum prototype machining. Here’s why it’s the preferred method:

- Accuracy:

CNC machines can achieve tight tolerances, crucial for industries like

aerospace.

- Speed:

Prototypes can be produced quickly, accelerating your product development

timeline.

- Scalability:

Suitable for single prototypes or small production batches.

- Waste Reduction:

Optimized processes minimize material waste, saving costs and supporting

sustainability.

FAQs

About Aluminum Prototyping

Why is aluminum ideal for

prototypes?

Aluminum is lightweight, durable, corrosion-resistant, and cost-effective,

making it perfect for creating functional prototypes.

How long does aluminum prototype

machining take?

Timelines depend on design complexity, but Sanwometal ensures fast

turnaround, often within a few weeks.

Can aluminum prototypes be used for

functional testing?

Yes, aluminum prototypes are robust and suitable for rigorous functional and

performance testing.

What industries benefit most from

aluminum prototyping?

Industries like aerospace, automotive, electronics, and consumer goods rely

heavily on aluminum prototyping for precision and efficiency.

Why choose Sanwometal for aluminum

prototype manufacturing?

We combine expertise, advanced technology, and a commitment to customer

satisfaction to deliver top-quality prototypes.

Conclusion:

Turn Ideas into Reality with Sanwometal

Aluminum

prototype machining are

revolutionizing product development across industries. At Sanwometal,

we’re dedicated to helping businesses in the USA and beyond achieve

their goals with precision-crafted prototypes.

Comments

Post a Comment